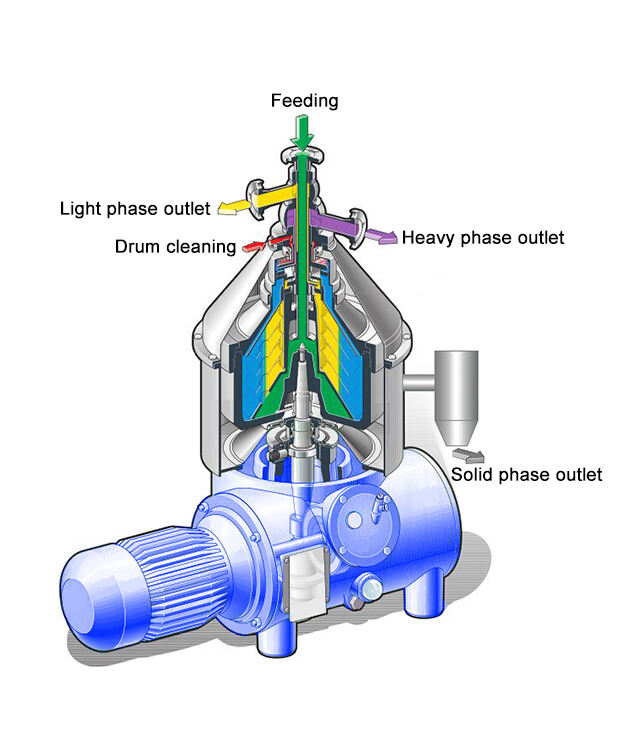

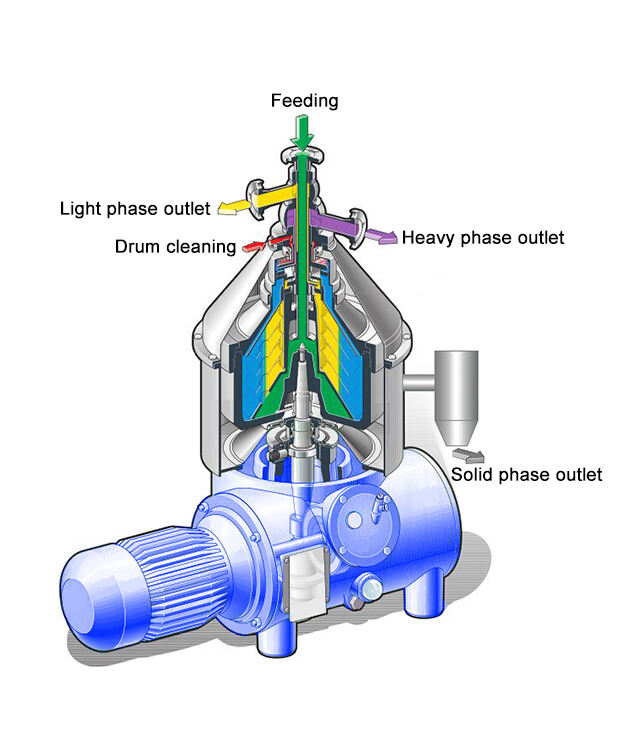

All the parts of the separator contacted with the materials are made

of stainless steel, which meets the requirements of food hygiene.

The

separator is mainly composed of import and export device, drum,

vertical shaft, transverse shaft, fuselage, speed measuring device,

brake device and motor. The centripetal pump structure is adopted for

discharging material, after separation, the material is discharged by

the centripetal pump, the output pressure is high (0-0.5 MPa), which can

be directly transported to downstream equipment. Its drum has been

accurately checked for dynamic balance, centrifugal friction clutch and

large helical gear pair are used to transmit power in power

transmission. The separator has the advantages of stable growth,

avoiding overload, small vibration, safety and reliability, simple

operation and convenient use. The bearings used in the separator all

adopt Swedish SKF brand to ensure the operation accuracy of the

equipment. If the separator is equipped with PLC electronic control

system, the program operation can be realized.

When the turbid liquid was fed into the high-speed rotating drum, it

enters the disc stack along the channel, under the strong centrifugal

force, the multi-components with different densities form three dynamic

concentric rings: a small amount of solid particles with the greatest

density move outward and accumulate on the wall of the drum to form the

outermost layer; the denser heavy phase liquid is thrown onto the lower

surface of the disc and slides down out of the disc area to form an

intermediate layer; the denser light phase liquid moves toward the

center of the drum to form the innermost layer. Then, the three

components are discharged from the drum by their respective channels.