A 600T/D sludge thermal drying project case from Chongqing in China

Publish Time:2022-10-31 Views:152

It is proposed to build a sludge thermal drying plant in the reserved land for a power plant in Chongqing. The project construction is divided into three phases. The scale of the first phase is 600 t/d (moisture content 80%). Considering the fluctuation range of sludge moisture content (75%-82%), the maximum solid flux of treatment is 150 t DS/d.

1.sludge components

Table 1 shows the average mud quality analysis results of the major sewage plants in Chongqing. The heavy metal content fluctuates to a certain extent, and the heavy metal index exceeds the standard in a small number of days. sludge disposal methods can use sludge co-incineration or building materials production. At the same time, since both incineration and building materials have a certain degree of pollution to the atmosphere, according to the existing regulations of the city, it is difficult to build such facilities. Therefore, it is recommended to use them as much as possible. sludge disposal at existing facilities in thermal power plants. The high calorific value of the dry base of dewatered sludge in the sewage plant is 6.5-11.2 MJ/kg. After independent thermal drying treatment, it can be disposed of by mixing in the power plant, and can replace a part of coal combustion and recycle heat energy.

2.Process of sludge termal drying

The moisture content of the dewatered sludge treated in this project is about 80%, and the moisture content is high. The sludge needs to be dried first and then entered into the incinerator of the thermal power plant to be mixed with coal in a certain proportion. Operating conditions depend on the energy balance of the drying and incineration systems.

The thermal power plant adopts pulverized coal furnace, the coal consumption is 6-10 million t/year, the mixing ratio of sludge and coal is about 0.9%, and the heat consumption required for drying to the solid content of 90% is very high. In addition, the safety investment of dust explosion-proof is relatively large. Therefore, the drying degree of sludge in this project is designed to be 30% moisture content.

Since the power plant can release a large amount of low-temperature and low-pressure steam while generating electricity, these steams are suitable as the heat source for sludge drying, and the steam can be used as the drying energy of the project.

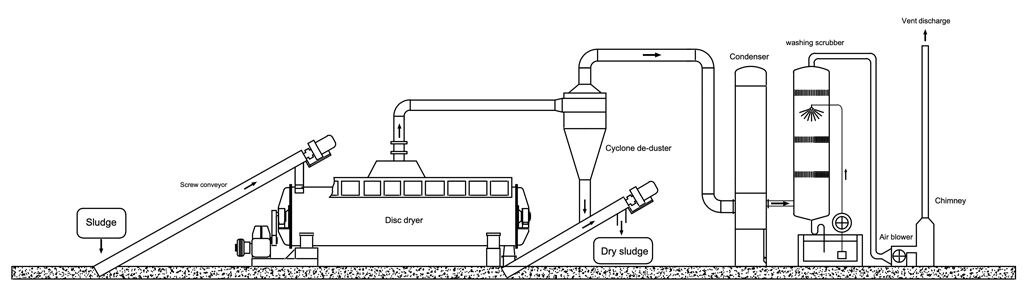

The process flow is thermal drying + co-firing process in thermal power plant

The dewatered sludge is dried by the steam of the thermal power plant, and the dried sludge is used as fuel and co-fired with coal for power generation and heating. The wet sludge is poured into the wet sludge receiving and storage silo after entering the factory and passed through the weighbridge. The sludge is pumped to the disc dryer, and the saturated steam is used as the heating medium to indirectly heat the sludge. The waste gas (steam and air mixture) generated during the sludge drying process is treated in two stages of dust removal and condensation. The waste water generated after the waste gas is condensed is discharged into the sewage pipeline, which is pretreated by the sewage treatment facility of this project and then discharged to the sewage treatment plant. deal with. The non-condensable tail gas is cooled by the tail gas condenser and drawn by the tail gas induced draft fan to the boiler of this Power Plant for incineration treatment and discharged up to the standard. Maintain the micro-negative pressure operation of the dryer, auxiliary equipment, and system pipelines to prevent high-concentration odor from overflowing.

The scale of this project is 600t/d (water content is 80%), with a total of 6 lines, each with a scale of 100t/d. The technological process consists of 7 parts, which are:

Wet sludge receiving, storage and conveying systems;

Main drying system (including dryer and Exhaust gas treatment system);

Dry sludge conveying and storage system;

Steam and condensate reuse system;

Circulating cooling water system;

deodorant system;

Electrical, instrumentation and control systems.

The sludge generated by the sewage treatment plant should be treated and disposed of for stabilization, harmlessness and resource utilization. Due to the low content of organic matter in the sewage treatment plant sludge, self-balancing of energy cannot be achieved, and external energy needs to be supplemented. wastewater and waste gas have a great impact on the surrounding environment, and it is difficult to implement such projects at present.

This project is located in the reserved land for the power plant, which systematically solves the energy demand problem of the sludge drying plant, and at the same time solves the problem of environmental pollution caused by water, mud and gas generated in the operation process, and realizes sludge treatment. For the purpose of disposal, the low-temperature and low-pressure steam of the power plant is used as the heat source for sludge drying, and the dried sludge is provided to the thermal power plant as fuel, realizing the recycling of sludge, which is in line with the concept of circular economy.