Application of screw press sludge dewatering technology in petrochemical industry

Publish Time:2022-01-13 Views:162

The screw press sludge dewatering machine as name as multi disc screw press,In recent years, it has been developed, innovated and popularized. Due to the characteristics of easy separation and no blockage, the screw press sludge dewatering machine has been widely used in many fields including the petrochemical field.

Characteristics and dewatering status of petrochemical sludge

1. Source of petrochemical sludge

sludge in the petrochemical field mainly refers to the oily solid waste produced in the process of oil exploration, transportation, refining and oily sewage treatment. The oily sludge produced in the crude oil extraction process mainly comes from the ground treatment system, the oily sludge produced in the oil extraction sewage treatment process; the transfer station in the oil field, the oil tank of the combined station, the sedimentation tank, the sewage tank, and the bottom of the oil separator. Oil sand and oil sludge removed from mud, light hydrocarbon processing plants, and natural gas purification devices, and oily sludge produced by drilling, operation, and pipeline perforation. tank) bottom sludge, flotation tank scum and biochemical tank residual activated sludge, etc.

2. Characteristics of petrochemical sludge

The oily sludge is huge, and if it is not treated and discharged directly, it will not only occupy a large amount of cultivated land, but also produce odorous gas, and will pollute the surrounding soil, water and air. The sludge also contains a large number of pathogenic bacteria, parasites (eggs), heavy metals such as copper, zinc, chromium, mercury, salts, and toxic and harmful substances that are difficult to degrade such as polychlorinated biphenyls, dioxins, and radionuclides. Among them, oily sludge from oil fields has been classified as hazardous solid waste and included in the management of hazardous waste.

The petrochemical sludge oily sludge has a wide variety of types, complex properties, high oil content, serious emulsification, fine particles and high viscosity, so traditional sludge dewatering equipment is difficult to dewater.

The petrochemical sludge dewatering technology with the screw-type sludge dewatering machine as the core

1. Muli disc screw press sludge dewatering equipment

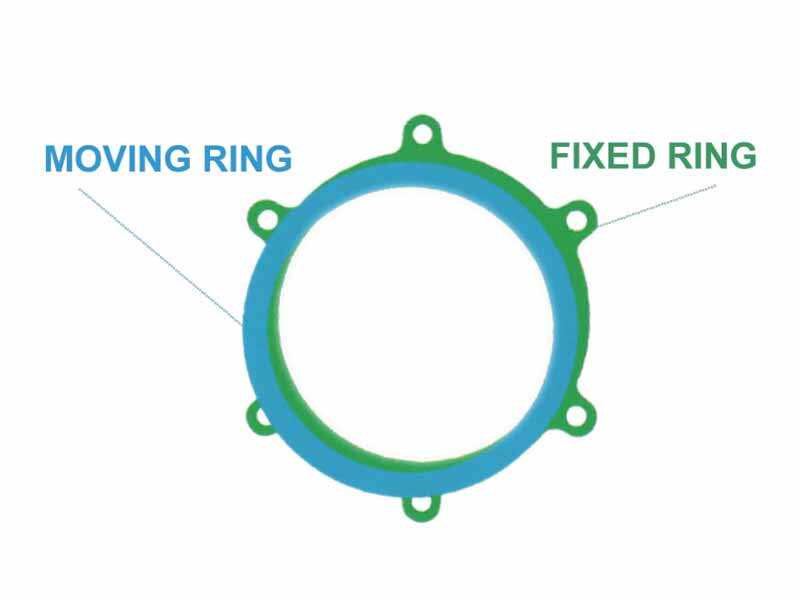

The main BODy of the multi disc screw press sludge dewatering machine is composed of multiple fixed rings, moving rings and screw shafts to form a filter unit. The machine has a compact structure, convenient operation and stable operation.

The main BODy of the sludge dehydrator is mainly composed of a filter BODy and a screw shaft. The filter BODy is divided into two parts: concentration and dehydration. When the sludge enters the filter BODy, the relative swimming of the fixed ring and the floating ring is used to make the filtrate pass through the lamination gap. It is quickly discharged to the outside, concentrated rapidly, and the sludge is pushed to the dewatering part. When the sludge enters the dewatering section, the space in the filter cavity is continuously reduced, the internal pressure of the sludge is continuously increased, and the back pressure of the back pressure plate at the mud outlet makes it dehydrated and the dry sludge is continuously discharged out of the machine.

The screw-type sludge dewatering machine adopts a movable fixed ring to replace the filter cloth. Under the rotation of the screw shaft, the movable plate is constantly displaced relative to the fixed plate, thereby realizing a continuous self-cleaning process and avoiding the common problems of traditional dewatering machines. clogging problem.

In addition, the influence of the dynamic and fixed ring structure of the multi disc screw type sludge dewatering machine on the fluid velocity in the filtration gap changes with the viscosity of the material. As the viscosity of the material increases, the more significant the effect of the dynamic and fixed ring structure on the increase of the flow rate, the more dewatering effect. obvious. Therefore, the screw-type sludge dewatering machine has strong resistance to oily sludge, is easy to separate, does not block, and does not require high-pressure washing with external water. It is clean and environmentally friendly, has no odor, and has no secondary pollution, and has self-cleaning function. Filter press dewatering of viscous sludge in the petrochemical industry.

2. Technology of multi disc screw sludge dewatering equipment for petrochemical industry

In view of the characteristics of high oil content, high viscosity, fine particles, and difficulty in dewatering of oily sludge in the petrochemical industry, Bioetp have independently innovated and developed a special screw-type sludge dewatering machine for the petrochemical industry. Has the following characteristics:

①Adopt the special screw shaft for the petrochemical industry, which is suitable for the push-flow characteristics of viscous materials in the petrochemical industry;

②Enhanced driving system to meet the requirements of large driving force for oily sludge;

③The dynamic fixed ring adopts materials with higher anti-corrosion performance, which is suitable for the operating environment with high chloride ions in the petrochemical industry;

④The whole equipment reaches the explosion-proof level of ExdIIBT4, which meets the strict explosion-proof requirements of the petrochemical industry;

⑤ Containerized equipment system designed for offshore oil platforms;

⑥Using a special flocculation dosing tank for oily sludge to overcome the characteristics of petrochemical sludge that is difficult to flocculate and easy to settle;

⑦Adopt the proprietary flocculant technology to reduce the specific resistance of oily sludge;

⑧ Small footprint and high dehydration efficiency.

1. The actual operation shows that the Bioetp screw-type sludge dewatering system has stable operation and good effect. Generally, the water content of oily sludge can reach 75%-80% after dewatering, which overcomes the problems of belt dehydrator and plate and frame filter press. It is easy to block, and the centrifuge is difficult to separate. It can not only greatly reduce the cost of dehydration, transportation, subsequent drying, incineration and other links, but also ensure the discharge or reuse of sewage treatment standards.

2. The Bioetp screw-type sludge dewatering system technology has good economic, environmental and social benefits. It has been popularized and applied in many petrochemical industry enterprises. In view of the experience summed up in the operation process, the system has very good performance in the petrochemical industry. application prospects.

Being a solid liquid separation solution provider, BIOETP is with rich experience in design and manufacturing the dewatering screw press machine. More important, BIOETP is able to provide overall solution for separation and conveying with the rich product line and strong fabrication and assembly capabilities.

So,if you have any industrial solid liquid separation requirement aroused, please feel free to contact BIOETP. You can find our contact on BIOETP official website www.bioetp.com.