Multi Disc Screw Press

FOR SLUDGE DEWATERING

Introduction:

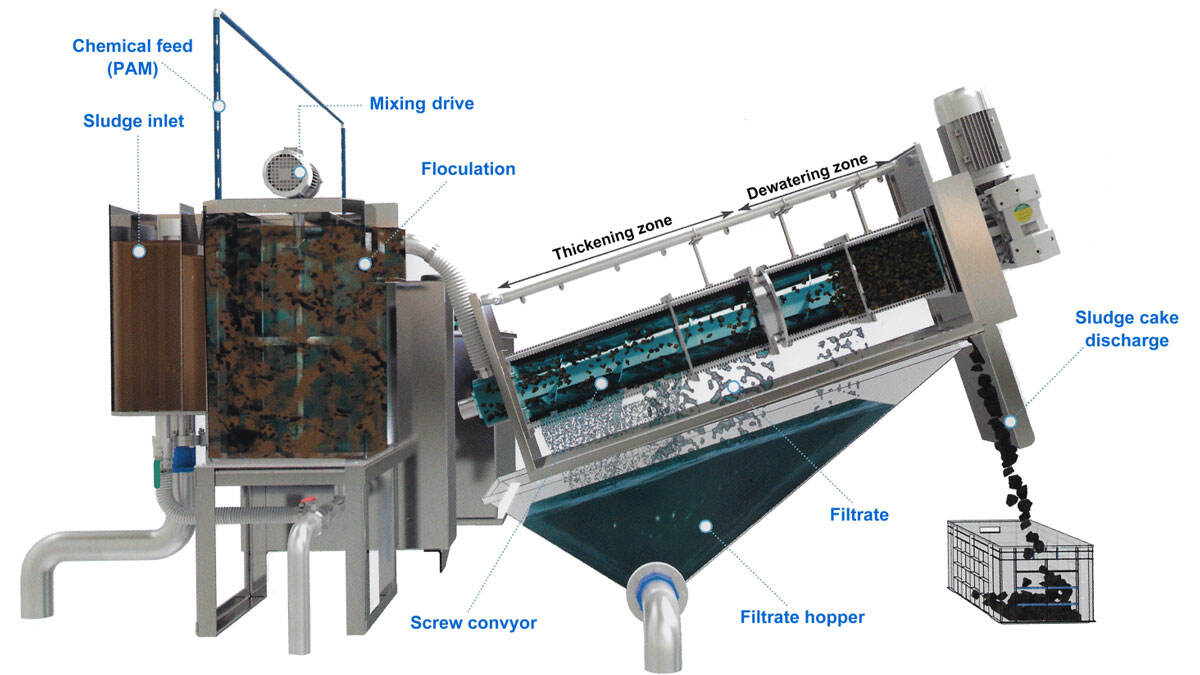

The multi disc screw press is referred to as the screw stacker. It is a new type of sludge dewatering machine that realizes sludge extrusion and dehydration through the strong extrusion force generated by the change of screw diameter and pitch, and the tiny gap between the moving ring and the fixed ring. solid-liquid separation equipment.

Application:

Widely used in sludge dehydration and solid-liquid separation of municipal and industrial wastewater in petroleum, food and beverage, animal husbandry, feed, pharmaceutical, chemical, machinery manufacturing, metal processing, printing and dyeing, papermaking and paint industries.