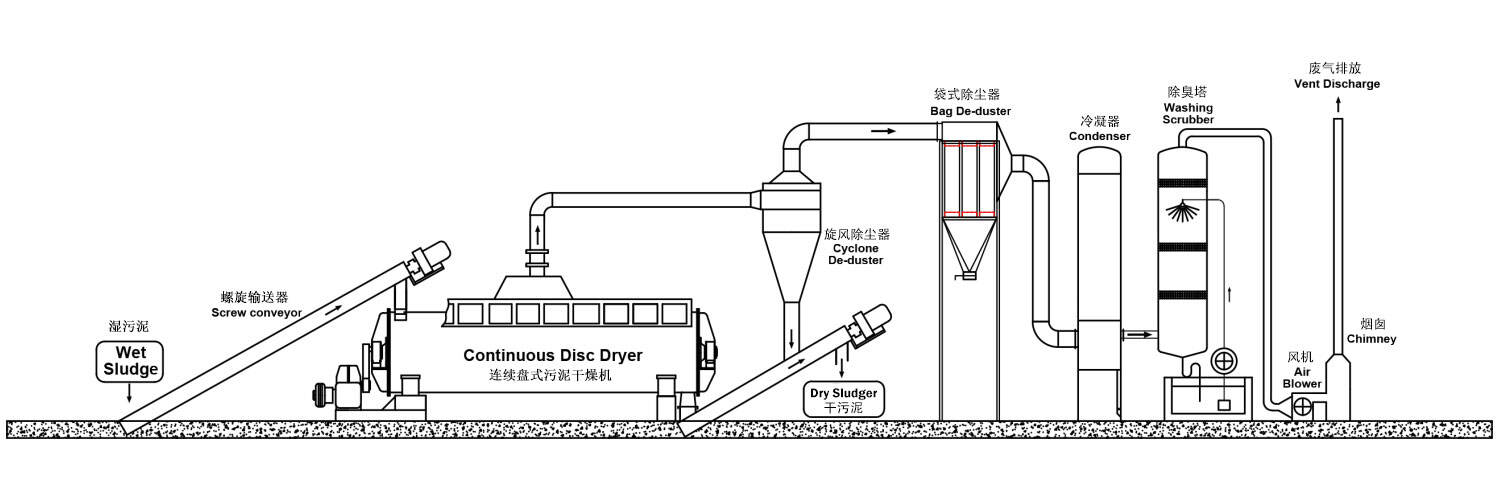

Continuous Sludge Dryer

Introduction:

The disc sludge dryer is composed of a horizontal shell and a heated rotor. Multiple heating discs are installed on the rotor, and the discs are equipped with adjustable angle pushers, which can be used during work. Heating the material can push the material along the direction of the discharge end. The steam distribution device inside the shaft can evenly distribute the steam to each heating disk, the steam flows in the disk to keep the heating disk at a constant temperature, and the condensed water is discharged through the special device at the shaft end.

Application:

It is widely used in the drying of industrial sludge and domestic sludge. Industrial sludge includes: petrochemical sludge, papermaking sludge, printing and dyeing sludge, leather sludge, Electroplating sludge, petrochemical sludge, coal washing sludge, water plant sludge, pickling sludge, drug residue sludge, construction sludge, pulp sludge, oily sludge, etc.; domestic sludge includes: Municipal sludge, sewage sludge, activated sludge, pond sludge, silt, mud, Mud etc. At the same time, it is also suitable for pulp sludge bio-fermentation bacteria residue, fish meal processing, starch processing, distiller's grains and other feed or food drying.