Multi-Disc Screw Press

FOR SLUDGE DEWATERING

Features

The Multi-Disc Screw Press

is a slude dewatering machine for wastewater treatment plant featuring the following advantages

1. Applicable for a wide range of sludege concentration.

2. Self-cleanung,clog-free filtration.

3. Low rotation speed,Reliable operation,low energy consumption,little noise.

4. Fully automatic control;Easy to operate and simple to maintain.

5. Small space Requirements.

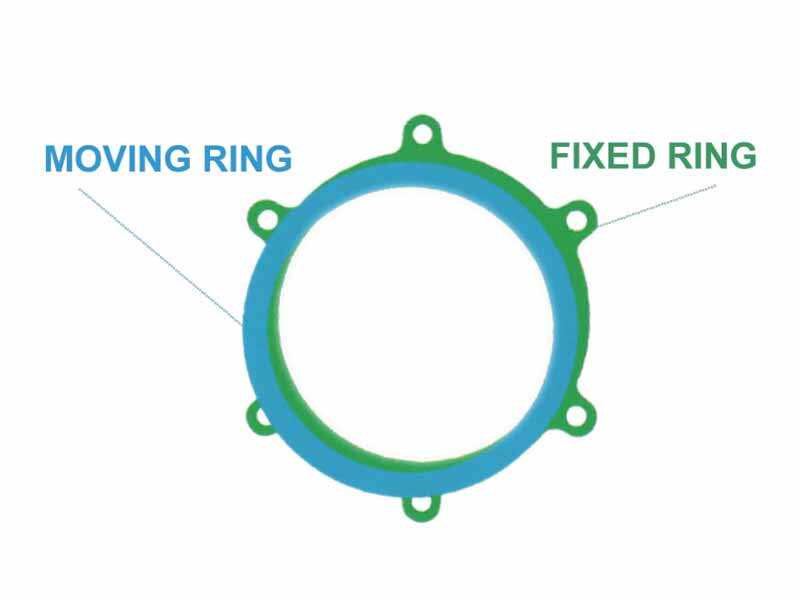

Double ring is more efficient

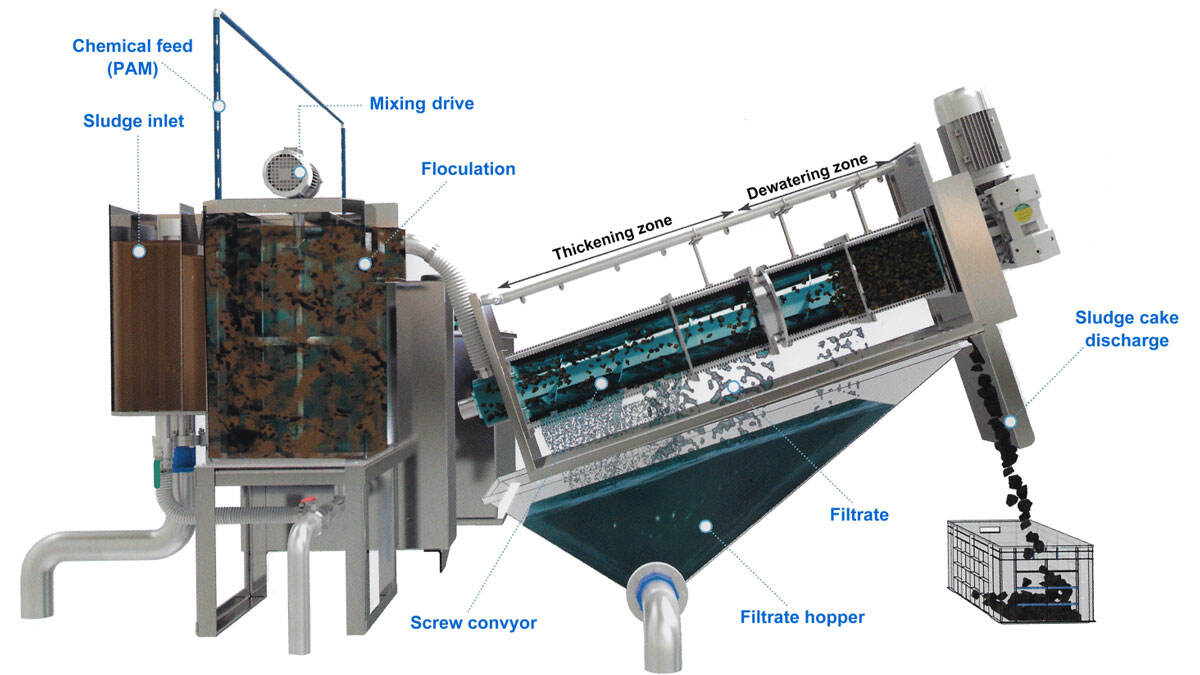

As clogging is avoided,the Multi-Disc Screw Press is able to handle oil sludge easily.

The series of finely machined fixed and moving rings placed alternately provides effcient filtration that remains clog free due to the continuous movement of the rings.This eliminates the needs for consumables like filter cloth etc.

Details

Operating Principle

ADVANTAGE & APPLICATIONS

Advantages: QY-SPD series Multi-Disc screw press is designed to handle handle various types of sludge in different capacities. The processing capacity is available from 1.5 m3/h to 180m3/h at 0.2% sludge concentration and 0.3m3/h to 28m3/h at 2% sludge concentration.

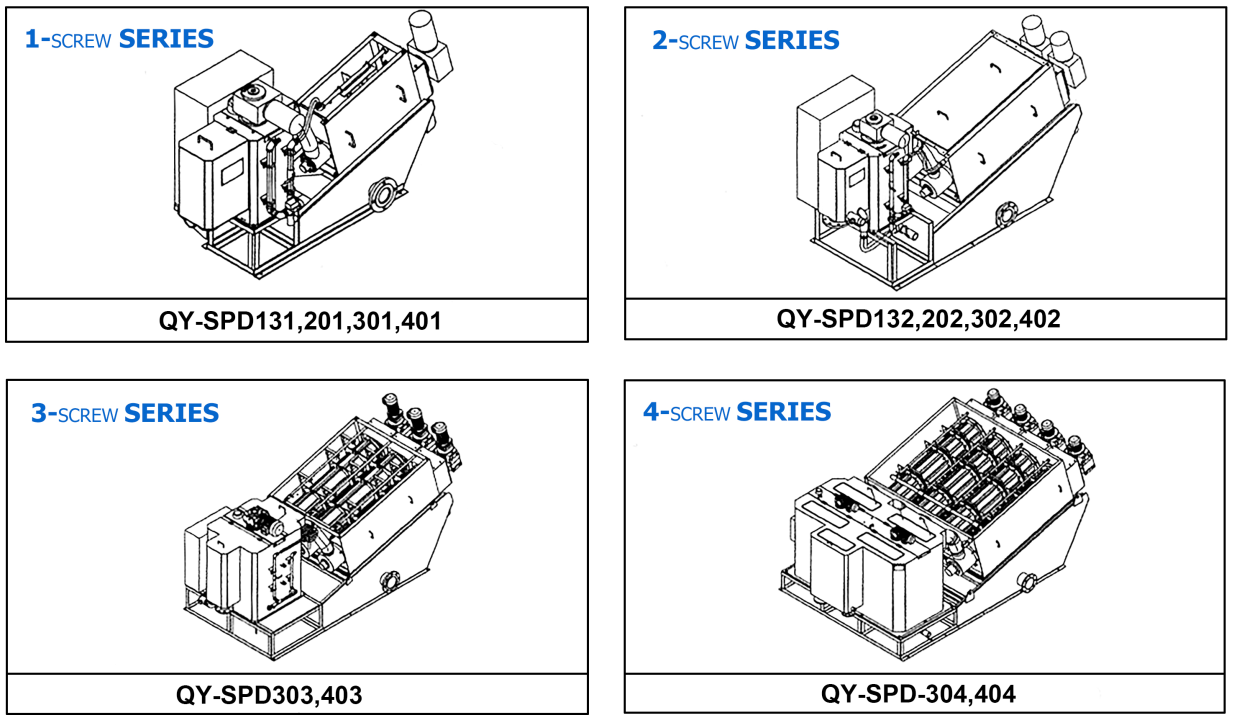

Due to its modular design and compact construction, the capacities can be easily scaled up by running system in parallel to meet almost any capacity as required. Single-screw, double-screw, triple-screw and quadruple-screw makes 1-screw series, 2-screw series, 3-screw series and 4-screw series separately.

Our experienced and trained team of engineers will help you with the installation, operation and maintenance training.

Application: Widely used in sludge dewatering and solid-liquid separation of municipal and industrial wastewater in petroleum, food and beverage, feed, pharmaceutical, paper and paint industries.

SPECIFICATION AND MODELS OF MULTI-DISC screw press

| Processing Capacity | sludge processing capacity(m3/h)under different sludge concentration | |||||

|---|---|---|---|---|---|---|

| Model | kg/h dry sludge(DS) | 2000mg/l (0.2%) | 4000mg/l (0.4%) | 10000mg/l (1%) | 20000mg/l (2%) | 25000mg/l (2.5%) |

|

QY-SPD-131 |

6-12 | 3 | 1.5 | 1.2 | 0.6 | 0.48 |

| QY-SPD-132 | 12-24 | 6 | 3 | 2.4 | 1.26 | 0.96 |

| QY-SPD-201 | 12-20 | 6 | 3 | 2 | 1 | 0.8 |

| QY-SPD-202 | 24-40 | 12 | 6 | 4 | 2 | 1.8 |

| QY-SPD-301 | 30-60 | 15 | 7.5 | 6 | 3 | 2.4 |

| QY-SPD-302 | 60-120 | 30 | 15 | 12 | 6 | 4.8 |

| QY-SPD-303 | 90-180 | 45 | 22.5 | 18 | 9 | 7.2 |

| QY-SPD-351 | 60-120 | 30 | 15 | 12 | 6 | 4.8 |

| QY-SPD-352 | 120-240 | 60 | 30 | 24 | 12 | 9.6 |

| QY-SPD-353 | 180-360 | 90 | 45 | 36 | 18 | 14.4 |

| QY-SPD-354 | 240-480 | 120 | 60 | 48 | 24 | 19.2 |

| QY-SPD-401 | 100-170 | 50 | 25 | 17 | 8.5 | 6.8 |

| QY-SPD-402 | 200-340 | 100 | 50 | 34 | 17 | 13.6 |

| QY-SPD-403 | 300-510 | 150 | 75 | 51 | 25.5 | 20.4 |

| QY-SPD-404 | 400-680 | 200 | 100 | 68 | 34 | 27.2 |