Bioetp Sludge Dryer System for oil Sludge Drying Treatment

Publish Time:2022-12-07 Views:232

Oily sludge mainly comes from the refining "three sludges" in the petroleum and petrochemical industry, that is, the oil separator bottom sludge, dissolved air flotation scum and excess activated sludge generated in the process of wastewater treatment in refineries; coal-to-oil, coal-to-oil Biochemical sludge, gasification wastewater pretreatment sludge, etc. produced by coal chemical industries such as gas and coal-to-olefins; sludge containing oil or organic solvents produced in the sewage treatment process of other chemical industries such as the pharmaceutical industry.

Oily sludge contains a lot of nutrients such as benzene series, phenols, heavy metals, nitrogen and phosphorus, and pathogenic bacteria and pathogenic bacteria, etc., and needs to be effectively disposed of safely. Deep dehydration by drying is necessary to reduce the moisture content to a reusable level (40% to 50%).

At the same time, the oily sludge has a high dry basis calorific value, and volatile organic gases are easily generated during the drying process, which is prone to safety accidents. Moreover, oily sludge is more sticky and has strong adhesion than ordinary sludge, and it is easy to stick to the heat transfer wall, which affects the heat transfer effect and even causes mechanical failures such as shaft holding and jamming. Therefore, it is necessary to study safe and reliable sludge drying technology.

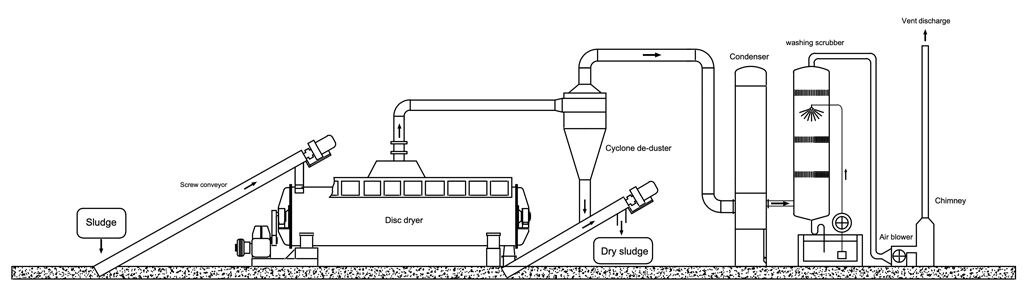

Process flow of Disc sludge dryer system

The disc sludge drying system consists of a heat source supply system, a sealed feeding system, a vacuum disc drying machine, a sealed discharge system, and a tail gas treatment system. The process flow is as follows:

The wet sludge silo has a short-term temporary storage function, and at the same time ensures the continuous feeding of the sludge dryer. The upstream dewatered sludge is transported to the silo through pipelines or sludge transport vehicles for storage. During operation, the sludge is fed to the dryer at a constant speed through a large-diameter screw pump, and the screw pump can ensure the airtightness of the entire system to a certain extent. The feeding speed is controlled by frequency conversion.

After the main machine is heated by steam, the sludge is dried by indirect heat transfer, and the residence time of the sludge in the main machine is controlled by frequency conversion. After the sludge is dried, it is discharged through the rotary discharge valve. Air inhalation ensures the airtightness of the system.

The dry sludge is first cooled by the water-cooled discharge spiral, and then transported to the dry sludge silo by the bucket elevator.

The tail gas treatment system reduces the content of dust, moisture and organic volatiles in the tail gas through "2-stage dust removal + 2-stage condensation". After the exhaust gas is drawn out of the drying chamber by the high-pressure fan, the dust reduction process is realized in the constant temperature cyclone dust collector. The temperature of the gas remains unchanged to prevent the condensation of water vapor from causing adhesion inside the dust collector. The bottom of the cyclone dust collector is discharged through the rotary discharge valve to ensure airtightness. Afterwards, the exhaust gas enters from the bottom of the spray tower, and rapidly cools down through the packing layer and spray area, removing most of the dust, volatile oil and a small amount of steam in the exhaust gas. The condenser quickly cools the exhaust gas to below 45°C, most of the water vapor and organic gas in the exhaust gas are condensed and condensed, and the condensate is pumped to the water tank of the spray tower, which is used as the make-up water for the spray tower to avoid sludge accumulation at the bottom of the spray tower. Abandoning external make-up water to reduce the amount of external sewage.

The working principle and features of the dryer

The disc sludge dryer is a horizontal structure. The inside of the equipment adopts a unique hollow main shaft, and disc blades are densely arranged on the hollow shaft. The steam flows evenly to the platter through the hollow shaft, heating the platter. The wet material is fully contacted with the hot surface of the disc under the agitation of the disc, and the water in the sludge completes the process of diffusion and evaporation. The generated water vapor gathers in the dome of the dryer, and is carried out of the dryer by the carrier gas, so as to achieve the purpose of drying.

The dryer has the following features:

Compact structure and small footprint;

Hidden weld seam design prevents wear and corrosion of weld seams and prolongs the service life of equipment

The scraping distance between the discs is 0.5cm, which can ensure the self-cleaning of the discs and ensure the heat transfer effect.

Multi-disc design, larger heating area.

Engineering Applications

The disc sludge drying system has been applied in many oily sludge drying projects, and the operation effect is good, and its safety and reliability have been fully verified.