What is Screw Press Sludge Dewatering Machine?

Publish Time:2022-05-17 Views:637

Screw Press Brief Introduction

In the process of waste water treatment, water-containing sludge of different properties is generally produced. The sludge dewatering equipment mainly reduces the water content of the sludge, and reduces the sludge volume, thereby bringing convenience to the subsequent treatment or disposal of the sludge. With the advantages of energy saving, stability, and high degree of automation, the screw press sludge dewatering machine, also named Multi-disc Dehydrator, occupies a place in the current sludge dewatering operation in the wastewater treatment industry, and it is still quickly recognized and accepted by the market.

Screw Press Main Components and Working Principle

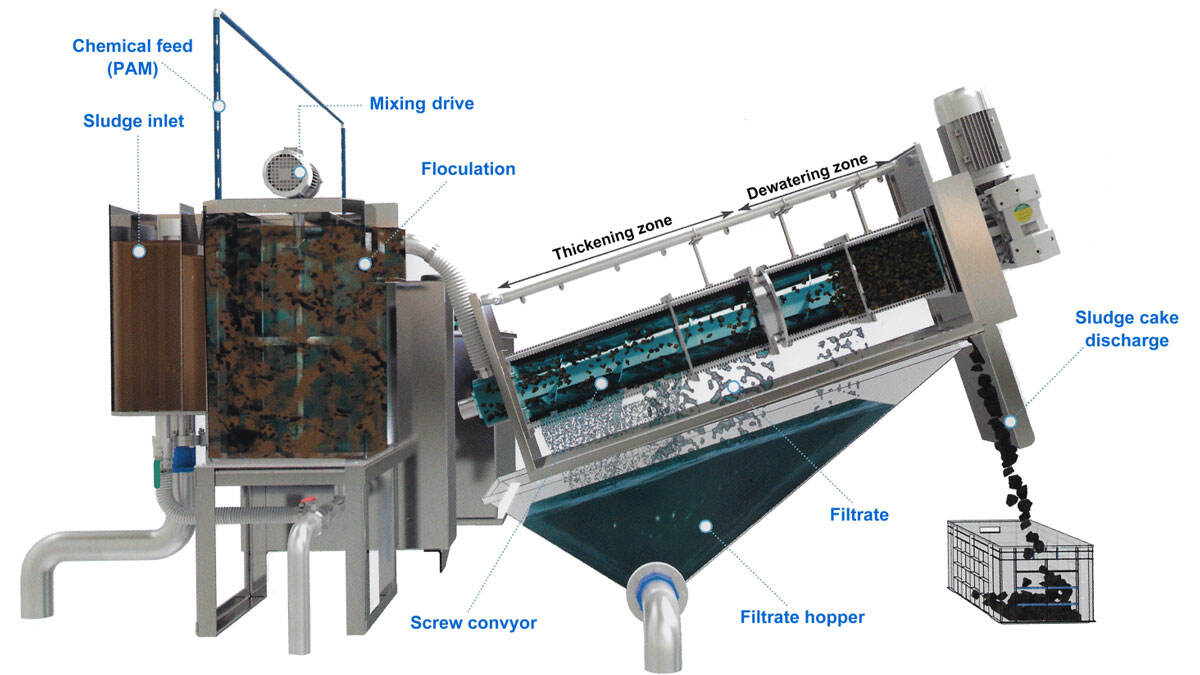

The screw press dewatering machine is mainly composed of a sludge premixing module, thickening & dewatering module and an electric control system. In the actual working process, the sludge is pumped to the metering tank by an external transfer pump. After rectification, the sludge further flows into the flocculation tank, stirs by agitator and fully reacts with the flocculants to form stable alum, and then passes through the upper part of the flocculation tank enters the dehydration screw. Inside the dehydration BODy, the alum blossoms are concentrated by gravity in the thickening section and at the same time advance to the dewatering section. In the process of advancing, with the gradual reduction of the filter gap and the screw pitch, and the blocking action of the back pressure plate, the sludge receives increasing pressure in the dewatering section, and the volume is continuously reduced, thereby achieving the purpose of dehydration.

The main BODy of the screw press dewatering machine is a filtering device formed by multiple fixed rings and floating rings superimposed in sequence, and the screw shaft penetrates through it. The front section is the thickening section, and the rear section is the dewatering section. The sludge thickening and squeezing & dewatering work are completed in one cylinder. In the process of spiral rotation, the floating ring and the fixed ring will form a dislocation movement, and the water will be discharged from the gap between the floating ring and the fixed ring. This replaces the traditional filter cloth filtration method with a unique and subtle filter BODy mode. The screw press follows the principles of the same direction of force and water, thin-layer dewatering, proper pressure and extension of the dewatering path, which solves the problems of easy clogging, inability to treat low-concentration sludge and oily sludge, high energy consumption, and complicated operations. The dewatering goal of high efficiency and energy saving has been achieved.