Sludge Dryers Manufacturers and Suppliers in the China

Publish Time:2022-07-12 Views:151

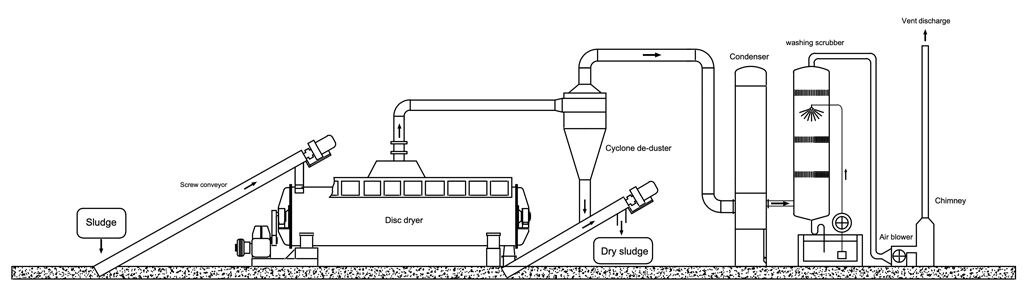

Nowadays, as environmental protection requirements are getting higher and higher, for many industrial enterprises, industrial sludge cannot be discarded and disposed of at will. How to properly dispose of the pollution of industrial sludge has become the premise for the long-term sustainable development of industrial enterprises. The industrial sludge dryer is the core equipment for processing and disposing of high-humidity and high-viscosity industrial sludge. The emergence of this equipment not only solves the problems of high water content, heavy odor, difficult drying and transportation of industrial sludge, but also sludge has also been fully resource utilization value. So what are the main equipment in the industrial sludge dryer production line?

The main equipment in the industrial sludge dryer production line:

1. Heating equipment: Industrial sludge drying equipment uses the principle of high temperature thermal drying to dehydrate wet sludge, so heating equipment is indispensable in the drying production line. There are many options for heating equipment, such as natural gas, biomass pellets, fuel oil, coal, biogas, etc. For those who have boiler flue gas and waste steam, they can also turn waste into treasure and make full use of waste. Heating by flue gas and waste steam.

2. Drying host: The industrial sludge dryer is an important equipment in the whole production line. The wet sludge and the high-temperature hot air realize heat exchange in the drying host, and evaporate a large amount of water. In order to improve the utilization efficiency of heat energy and shorten the drying time, there is a dispersing and crushing device inside the drum, which can quickly separate the bulk materials and increase the contact area between the materials and the high-temperature hot air. In addition, there is a spirally distributed lifting plate device in the drum, which continuously throws and sprinkles the material, so that the material is fully integrated with the hot air, improves the production efficiency, and reduces the residence time of the material in the drum.

3. Exhaust gas treatment equipment: During the operation of the industrial sludge dryer, Exhaust gas treatment equipment can be used to collect the exhaust gas and dust discharged from the cylinder for treatment. Generally speaking, common dust removal equipment includes cyclone dust collector, bag filter, desulfurization scrubber and other equipment. Different equipment has different application scope and different advantages and characteristics. Therefore, the technical staff of the industrial sludge dryer manufacturer will design an exclusive waste gas treatment plan according to the exhaust gas emission of different users.

As a manufacturer and supplier of industrial sludge drying equipment from China, we have a mature industrial design system, advanced manufacturing technology, and a perfect parts supply ecology to ensure the manufacture of a complete set of sludge drying systems.

We produce disc type sludge dryers. With the same equipment investment, a larger drying area can be obtained, and the drying cost of materials can be reduced by 30%. At the same time, due to its unique disc design, the friction between materials and equipment is reduced. Wear, 25% longer lifespan.

Double-blade disc,

higher heat transfer efficiency

Concealed welding reduces equipment wear

Compact structure, smaller footprint