The process description of Screw Press Sludge Dewatering Machine

Publish Time:2022-01-07 Views:362

Before this, we have introduced a lot of articles about sludge dewatering. Today we will introduce the working principle of sludge dewatering machine.

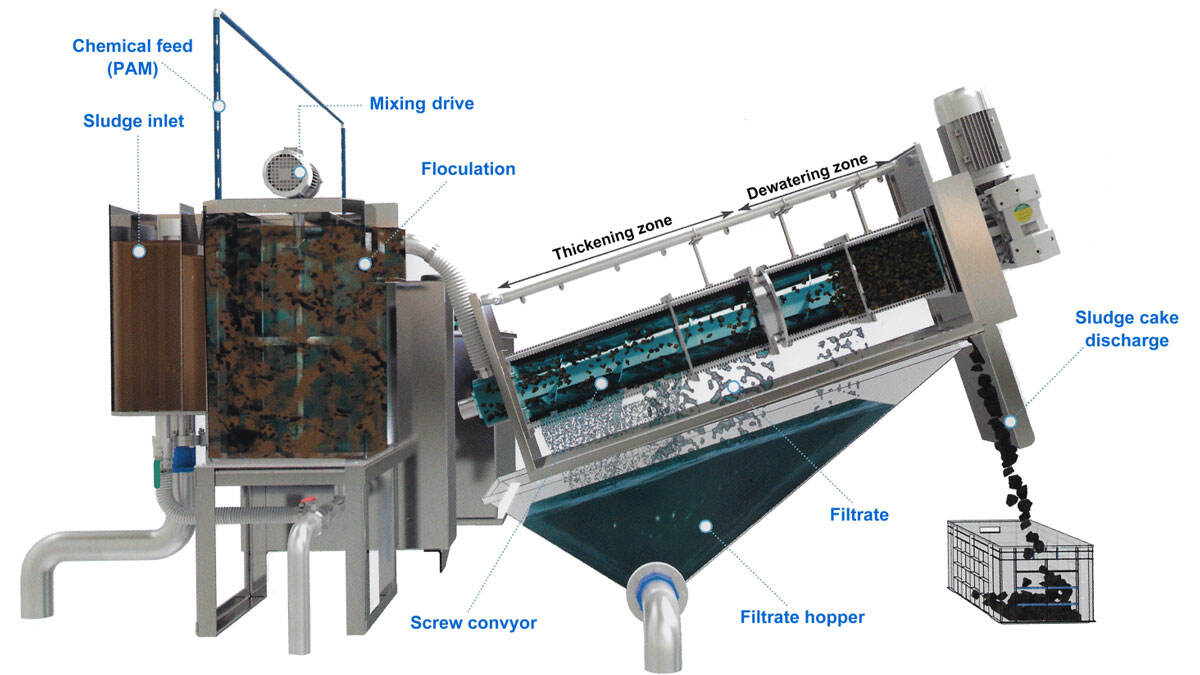

Working Principle: When the sludge is thickened by gravity, the sludge is transported to the dehydrating section. In the process of advancing, with the gradual smaller of the seam and pitch, and the obstruction of the back pressure plate, the internal pressure is produced and the volume is reduced continuously to achieve the purpose of full dehydration. screw press sludge dewatering machine, screw laying machine sludge treatment process, screw type sludge dewatering machine, screw press sludge treatment process flow sheet.

1. Through flocculation experiments, determine the type and proportion of matching flocculants. If two flocculants are needed for effective flocculation, it is recommended to select a dewatering machine with two flocculation tanks. The mixing device should be set up in the sludge tank. The dewatering machine should continuously mix the sludge before and during the operation, so as to ensure the relative stability of the sludge concentration.

2. Before running the QY-SPD series Multi-Disc screw press type sludge dewatering machine, the flocculant solution should be first prepared with the foaming device. Among them, the normal dilution ratio of polymer flocculant is 500-1000 times. The sludge is transported through the sludge pump, and the flocculant is pumped through the dosing pump. The flocculant is added to the flocculation mixing tank according to the corresponding proportion. The mixture is fully mixed to form the alum flower through the mixer, and the gravity concentration is carried out in the concentrating section. The filtrate is discharged from the filter seam of the concentrated part. The filtrate has a low solid content and is directly reflued to the original pool.

3. The concentrated sludge moves forward along the helix axis, and fully dehydrates in the dehydrated part under the action of various resultant forces. The filtrate of the dehydrating part has high solids content and can be reflued to the flocculation tank for dehydration.

4. After dewatering, the mud cake is discharged from the outlet of the mud cake outlet, and is transported to the mud truck directly or through the shaft-less screw conveyor for reuse.

Bioetp series Multi-Disc screw press is designed to handle handle various types of sludge in different capacities. The processing capacity is available from 1.5 m3/h to 180m3/h at 0.2% sludge concentration and 0.3m3/h to 28m3/h at 2% sludge concentration.

If you want to know more about our product, please contact us on bioetp.com!